(name of the tire)

(tire description)

Technical Details

- Hybrid trailer compound

- Improved rib pattern

Hybrid trailer compound.

The Conti Hybrid HT3 uses new rubber compounds with less heat development in both tread and sidewall. The tread polymer improves rolling resistance and increases service life while the optimised sidewall compound improves the fuel efficiency of this trailer axle tyre.

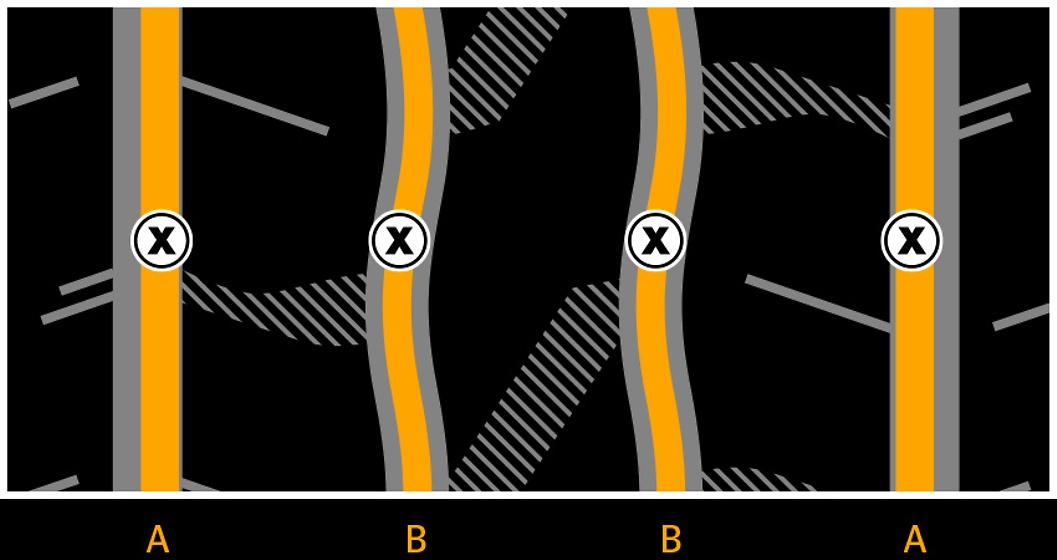

Improved rib pattern with new sipe technology.

The enhanced pattern structure in the rib area offers more mileage performance and better fuel efficiency. Newly introduced 3PMSF marking thanks to innovative pocket sipes located in the intermediate ribs.

ContiLifeCycle

- Regrooving

- Retreading

| Size | Depth (mm) | Width (mm) |

| 385/65 R 22.5 HL | 3.5 | A: 10 B: 8 |

| 385/55 R 22.5 | 3.5 | A: 10 B: 7 |

| 385/55 R 19.5 | 3.5 | A: 10 B: 7 |

Using our premium hot retreading service ContiRe™, you give new life to your worn Continental truck tyre and realise the full economic performance of the tyre. ContiRe™ production is compatible to how we manufacture our new tyres – using the same profiles and compound mixtures. Exclusively we use Continental casings, which are retreaded from bead to bead. This method also renews the sidewalls, and the tyres remain regroovable.

To ensure a premium finish, every tyre is put through durability and safety tests in adherence to a standardised quality system. Consequently, every ContiRe™ tyre is covered by our warranty. All this coupled with outstanding mileage makes our ContiRe™ the best choice of retreadable tyre.

During hot retreading, the process of applying the tread material is virtually identical to the production of a new tyre.

The tread material is taken directly from the extruder and applied to the buffed casing. Afterwards the tread/casing assembly is cured in a vulcanisation mould with the required tread pattern. The pattern on the tread is formed during the vulcanisation process just as it is when a new tyre is made.

Our hot retreaded truck tyres are retreaded from bead to bead. The main advantage of this principle is that the sidewalls are renewed, ensuring that the quality of the hot retreaded tyre is comparable with that of a new tyre.

Downloads

Still have questions?

Just ask.

We are happy to answer all your questions and support you with our tyre expertise.