Simulation

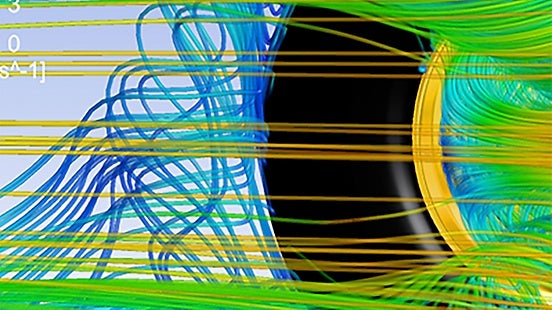

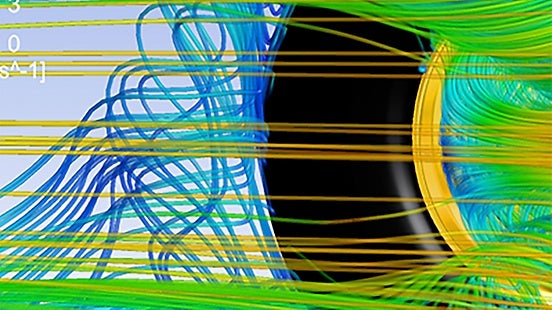

In the past, simulations were mainly used in the tyre sector as an additional product development measure to complement testing. Today, simulation methods have become far more reliable and precise. But is it now possible to predict all characteristics of the finished tire reliably and accurately?

Predicting its behaviour is therefore more complicated than for metallic materials.

Rubber is a complicated material. Due to its viscoelastic nature, replicating it – especially in combination with other equally intricate component parts of a tire – is a very complex task. Predicting its behaviour is therefore more complicated than for metallic materials. However, with the help of more digitalised development processes and increasing hardware performance capabilities, simulation methods have achieved a level of maturity that allows them to be increasingly used as standard procedure in the tire sector as well.

Consequently, simulations are now in a position to always compete with other test methods. The method ultimately selected will be the one that is most effective and delivers the best results. There are tyre characteristics which are relatively easy to test but difficult to simulate, while others can readily be simulated but testing would be a very laborious process. The rolling resistance of an existing tyre can be determined relatively quickly by drum testing, for example, whereas a simulation method would involve far greater expense. However, if the aim is to predict wear under specific driving conditions for a tire that has yet to be developed, testing would be extremely costly. In this case, simulation would be the preferable option.

Added to which the product’s characteristics are always subject to a certain degree of variation

Simulations for evaluating performance

There is currently a strong trend towards using simulation methods to assess “additional performance”, particularly in relation to handling dynamics and the associated tyre characteristics. The ideal scenario for tyre development would be if simulations could provide a preview of what a tyre’s construction should look like for it to achieve the desired characteristics, in the best possible way, using existing technology.

In the real world, simulation is not yet sufficiently accurate in all areas. Added to which the product’s characteristics are always subject to a certain degree of variation due to the materials used. This explains why today’s development process still has to include one or two loops using actual components in order to evaluate performance.

Growing number of target approvals

In recent times, there has been a sharp increase in the variety of vehicle models produced by the automotive industry. On top of this, each model comes with a choice of many different sizes of tyre to satisfy varying customer preferences. Consequently, the proportion of original equipment developments (“target approvals”) is rising, despite the overall volumes involved possibly remaining the same or even declining. This results in great complexity and, in particular, huge expenditure on testing – for tyre and vehicle manufacturers alike. Given the likely smaller volumes involved, both parties have no option but to cut their development costs per target approval substantially while maintaining the same high standard of quality. Virtual development therefore offers enormous potential, enabling a vehicle manufacturer to combine a tyre model with their vehicle model so that it can be tested and fine-tuned on a computer or in a driving simulator.

Related articles

-

2023/05/18X-ray and CT tyre analysisRead more

2023/05/18X-ray and CT tyre analysisRead more -

2023/05/18Tyre DesignRead more

2023/05/18Tyre DesignRead more -

2023/05/18Special LabsRead more

2023/05/18Special LabsRead more