#Agriculture

How Our Tyres Reduce Soil Compaction

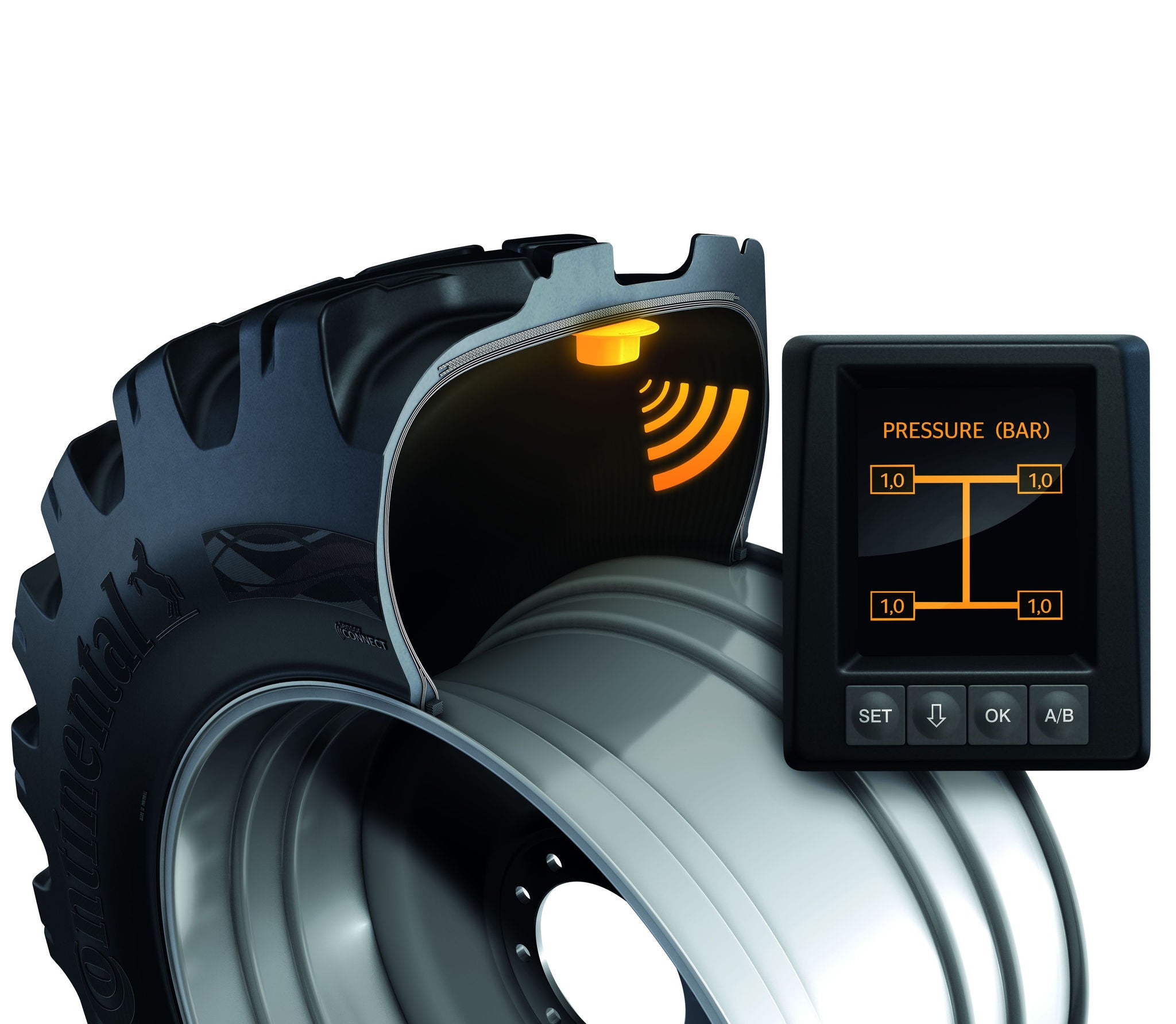

From technology to digital solutions

The average size of tractors has increased over recent years and heavy tractors increase the risk of soil compaction damage. One way of reducing this potential damage is to fit larger tyres that operate at lower inflation pressures. However, we have developed further measures in both the design of our tyres and through the use of our digital technologies to help reduce compaction and manage tyres more efficiently.

Soil compaction has serious effects on agricultural production and damages the environment. Soils in wet areas are especially prone to damage and some soils are more sensitive to compaction than others.

Soil compaction:

- reduces crop yield and quality

- increases the number and depth of cultivations needed

- increases harvesting problems

- increases wear on tillage machinery

- increases runoff and erosion

- reduces the efficiency of nitrogen fertiliser use

Nitrogen unused by the crop will also cause water or air pollution.

Moderate compaction can cause overall yield losses of 5% or more. On an average yield of 5 tonnes of barley per hectare (40 cwt per acre) at £100 per tonne, gross margins will be reduced by £2500 per annum on 100 hectares. An investment in tyres which minimise compaction can therefore be recouped in two to three years, depending on the number of hours the machine is used and the choice of tyres.

So, how can our tyres help?

We have a dedicated agricultural tyre research and development facility in Lousado, Portugal. It designs and produces agricultural tyres that can help to offset the potential damage heavy machines can cause to soil. The pinnacle of this is very high flexion (VF) tyres with a single bead wire that are more flexible and can be run at lower pressures. VF tyres carry 40% more load than a standard tyre at the same pressure. Alternatively, in the field, the pressure of VF tyres can be lowered by 40% compared to standard tyres, even when carrying the same load. This spreads the weight of the vehicle over a larger surface area and reduces soil compaction.

The bead

The strength of the bead core is an important factor in determining the pressure a tyre can be operated at. Having pressures too low can cause the tyre to slip the rim, but with our single wire bead construction, tyres can be operated at lower pressures more safely. Our agricultural tyres also feature both a rectangular and hexagonal bead core.

The more common rectangular shape is used in TractorMaster, VF TractorMaster and VF TractorMaster Hybrid tyres. The bead is constructed using a single wire and therefore differs to some common radial tyres which use multiple wires. The benefit is that, with fewer joins, the bead has fewer weak points, unlike those which require upwards of 10 wire joins to make the core.

The hexagonal core has been developed specifically for the front wheels of combine harvesters to help carry the high load of the header unit. Our CombineMaster tyre has a compact structure that helps the bead to carry the heavy weight more efficiently. The single wire construction also makes the tyre easier to fit and helps it to hold the rim more reliably to prevent slippage. For the steer axle wheels on a combine, we have developed the VF CombineMaster which features a rectangular bead core for high torque transmission from the rim to the tyre.

- Rectangular Bead

- Hexagonal Bead

Technology

Using our Agriculture TireTech app can help to reduce soil compaction by calculating the best operating pressure. It can also take in to account any implement or additional weight being used. If a mounted or trailed implement is added to the tractor the app will calculate the optimum operating pressure based on the overall load. The app is available for most mobile devices and has all our tyre specifications stored so the operator only needs to select the tyre, the weight of the tractor and any implement being used to calculate the optimum operating pressure.

When operating on the road, or in the field, tyre pressures can change due to heat build-up. This can be managed using ContiPressureCheck, a heat and pressure sensor that relays information about the tyre to a handheld or cab mounted display. ContiPressureCheck monitors pressure and heat to enable the operator to adjust the pressure when changing from road to field or when moving to fields with different soils. This can significantly reduce compaction by informing the operator that the pressure needs to be changed.

- Agriculture TireTech App

- ContiPressureCheck

The solution

A combination of technology in the tyre such as the bead, and digital solutions such as the TireTech app and ContiPressureCheck, have been combined in our tyres to help reduce soil compaction. The app is free to use and ContiPressureCheck can be specified on purchase or retrofitted to Continental tyres manufactured since 2017. Choosing VF tyres will be beneficial for machines that carry heavy loads or need to be operated with lower tyre pressures. Therefore, choosing VF tyres in conjunction with Continental’s digital solutions is the best way to alleviate soil compaction and reduce the impact of heavy machines on the land.

Related articles

-

2024/04/09Customer StoriesRead more

2024/04/09Customer StoriesRead more -

2023/05/24Warranty extension up to 10 yearsRead more

2023/05/24Warranty extension up to 10 yearsRead more -

2023/06/12With Heart & SoilRead more

2023/06/12With Heart & SoilRead more