#Agriculture

Improving tyre flexibility

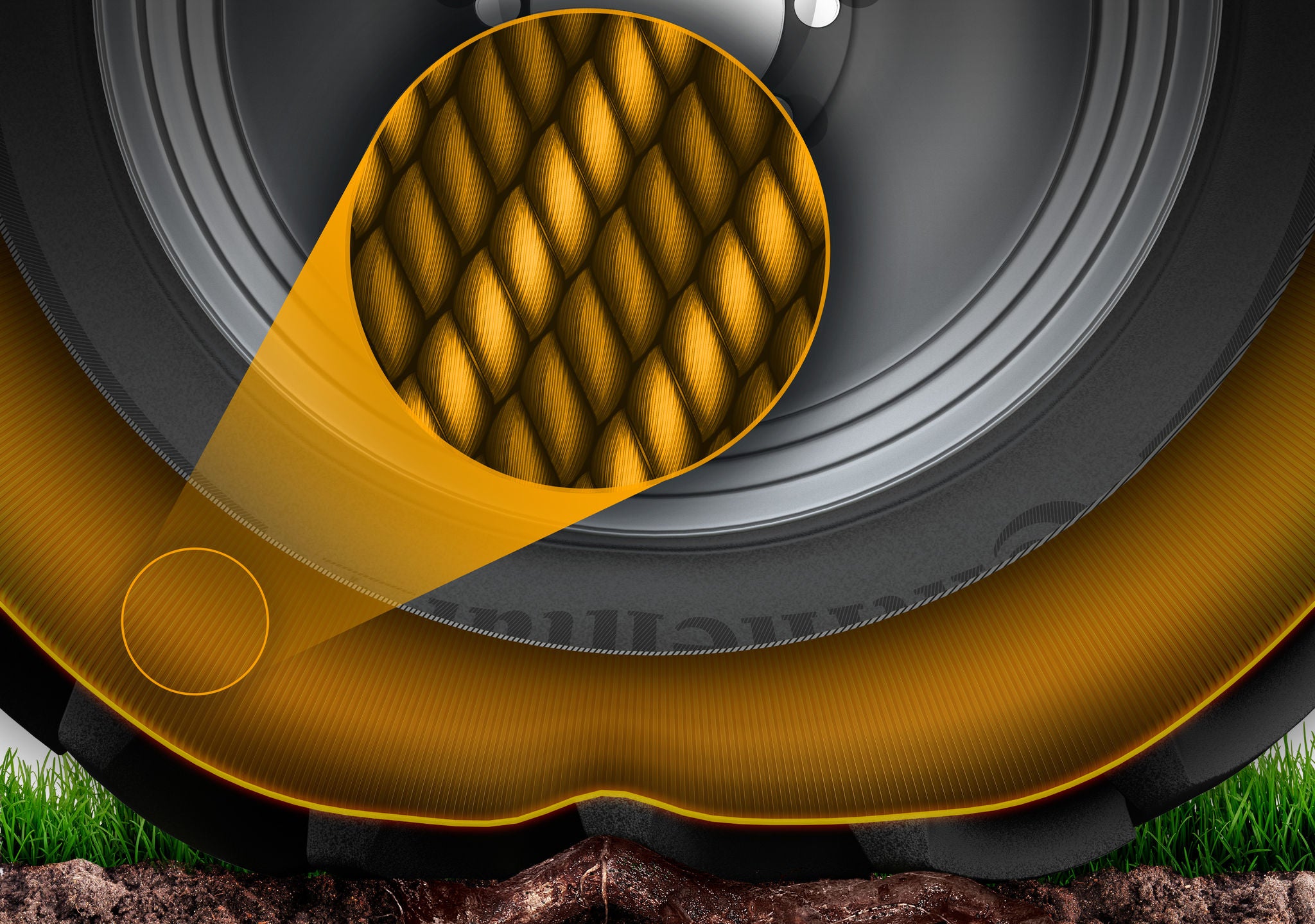

Our N.Flex Technology

How we made our tyres more flexible and resilient to damage

Our new range of agricultural tyres were developed by our designers and engineers in Germany and Portugal. The tyres have been manufactured at a state-of-the-art factory in Lousado, Portugal since 2017. An important development that features in all the new tyres is N.flex, a patented nylon that improves the flexibility of the tyre which reduces flat spots and makes the tyre more resistant to stress.

The goal was to design a material that had comparable resistance to nylon but with further elongation and better properties to return to its shape. A cultivator is designed to eject stones to prevent damage and we wanted to emulate this in the material of the tyre so that if the tyre hits a stone, it can withstand the impact.

N.flex uses nylon because it is light and has a good chemical connection to the rubber of the tyre. We treat it to help it bond with the rubber and this is what helps the tyre to be more flexible and more resilient to stress. From decades of tyre-making experience, we have developed N.flex to give our tyres greater stability. Our N.flex nylon has a stronger connection to the rubber providing greater flexibility, durability and resistance to heat deformation.

Resistance to heat deformation also helps to reduce flat spots which occur when the tyre cools in a parked position following long periods of work. We have tested our tyres extensively to increase the tolerance of the tyre to the pressures of heavy agricultural work and now offer a 10-year warranty to back up the technology we have developed. In our next post we will focus on how the tread of the tyre has been designed with a unique lug configuration to offer greater grip in the field and operator comfort on the road.

Related articles

-

2024/04/09Customer StoriesRead more

2024/04/09Customer StoriesRead more -

2023/05/24Warranty extension up to 10 yearsRead more

2023/05/24Warranty extension up to 10 yearsRead more -

2022/08/08Multi-Purpose TyresRead more

2022/08/08Multi-Purpose TyresRead more